-Formulation:

The ingredients used in ice cream production are: fat;milk solids-non-fat (MSNF);sugar/non-sugar sweetener;

emulsifiers/stabilisers;flavouring agents;colouring agents.

-Weighing, measuring and mixing:

Generally speaking, all dry ingredients are weighed, whereas liquid ingredients can be either weighed

or proportioned by volumetric meters.

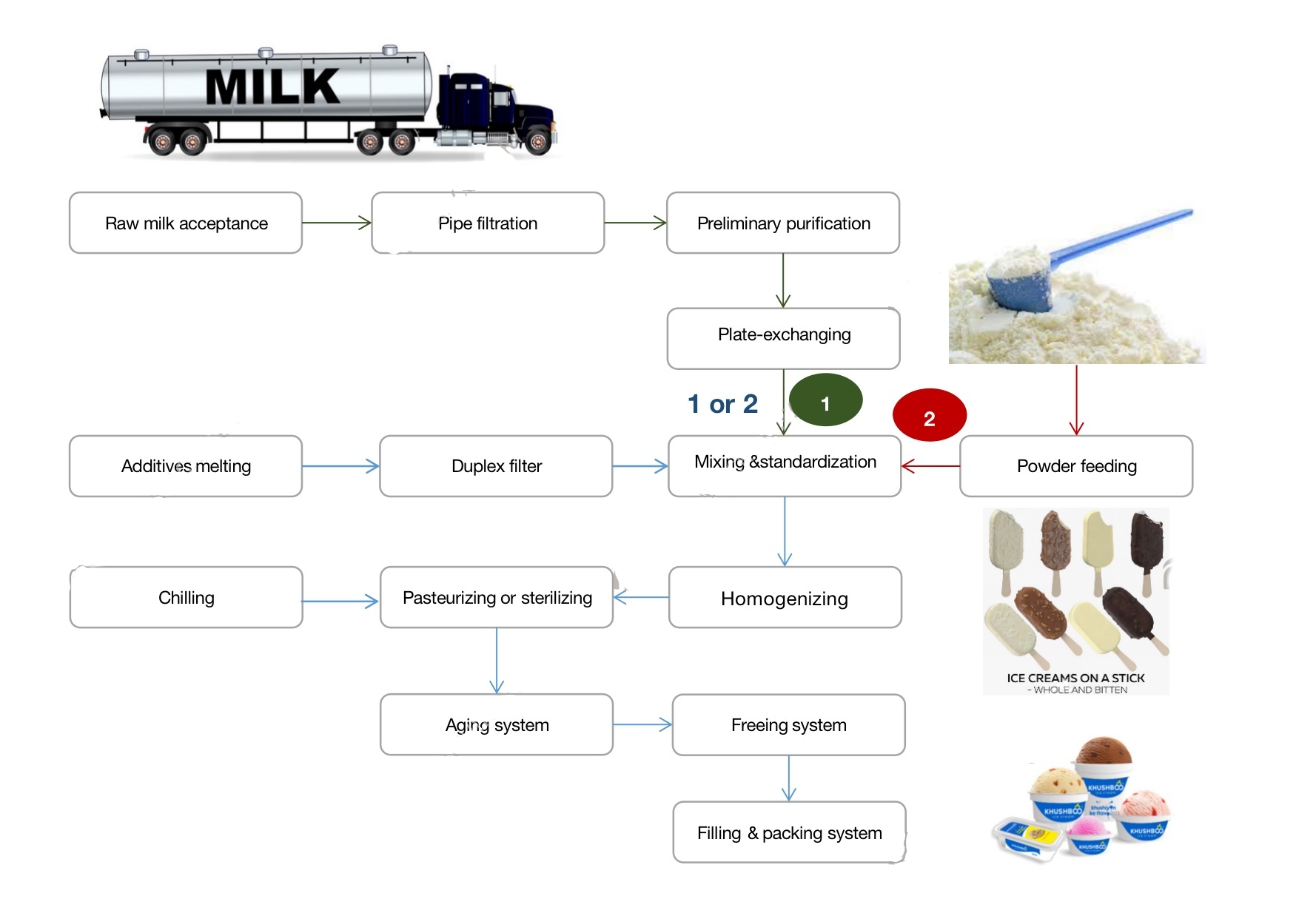

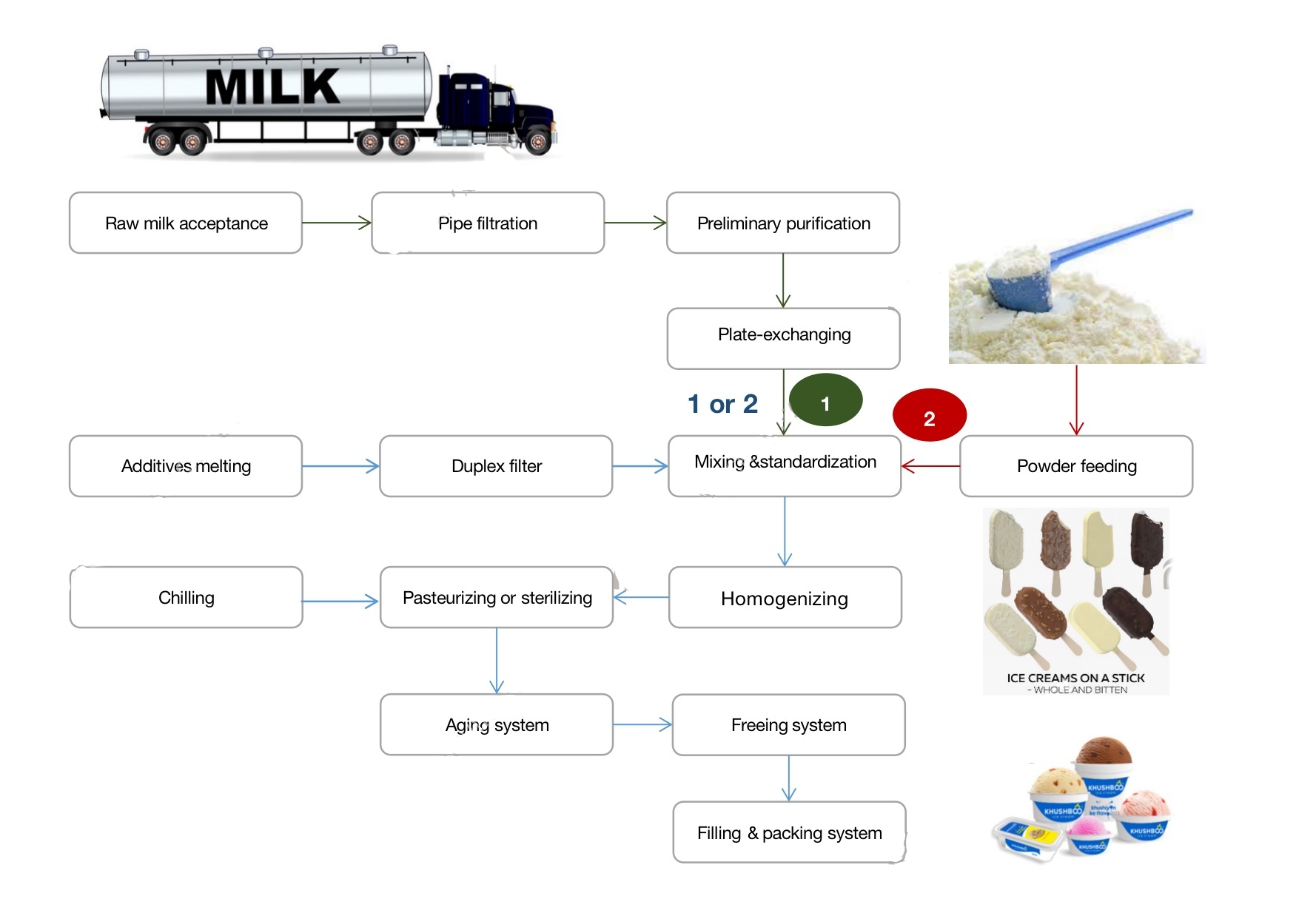

-Homogenisation and pasteurisation:

The ice cream mix flows through a filter to a balance tank and is pumped from there to a plate heat exchanger

where it is preheated to 73 – 75deg for homogenisation at 140 – 200 bar, the mix is pasteurised at 83 – 85deg

for about 15 seconds then cooled down to 5deg and transferred to an ageing tank.

-Ageing:

The mix must be aged for at least 4 hours at a temperature between 2 to 5degc with continuous gentle agitation.

Ageing allows time for the stabiliser to take effect and the fat to crystallise.

-Continuous freezing:

•to whip a controlled amount of air into the mix;

•to freeze the water content in the mix to a large number of small ice crystals.

-Filling in cups, cones and containers;

-Extrusion of sticks and stickless products;

-Moulding of bars

-Wrapping and packaging

-Hardening and cold storage

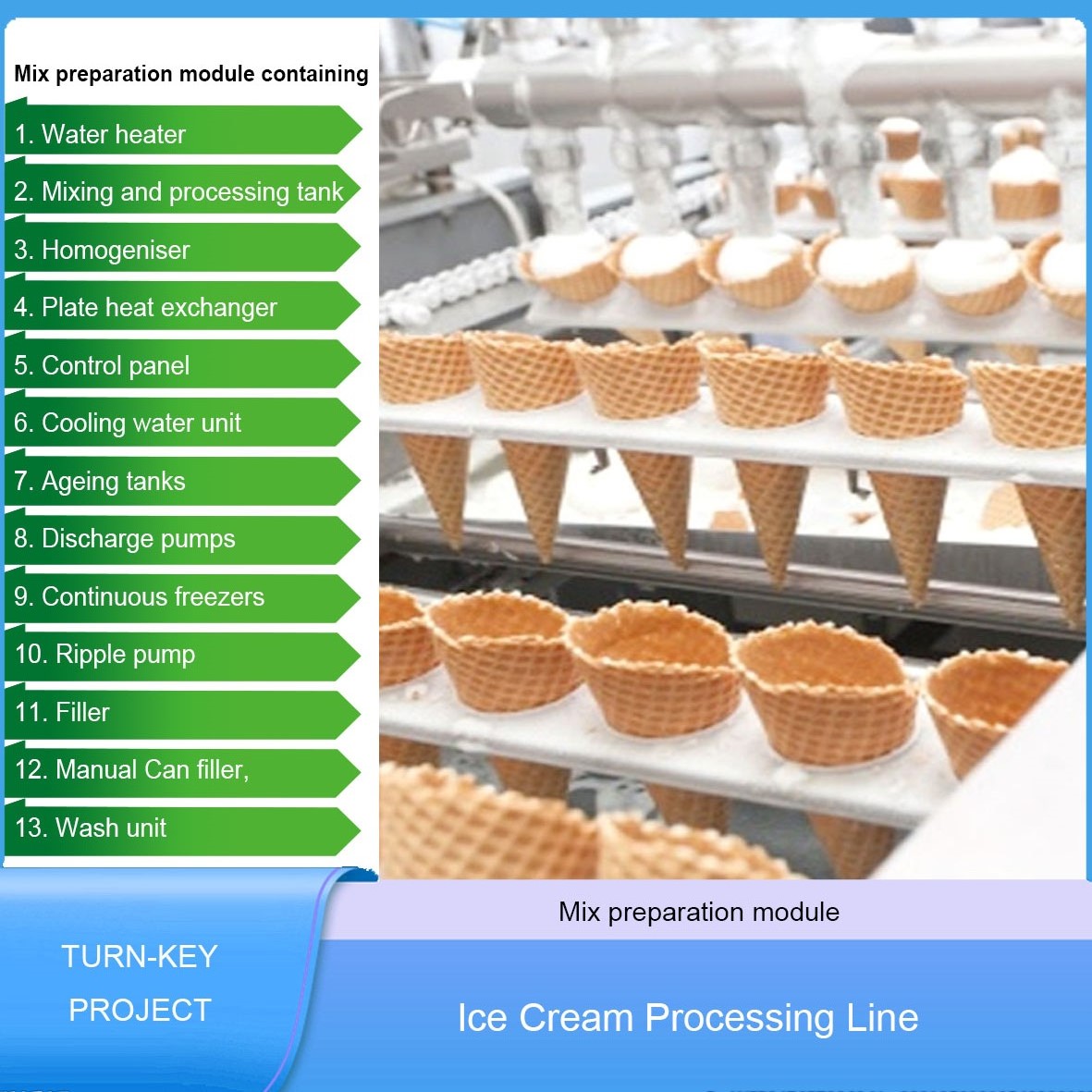

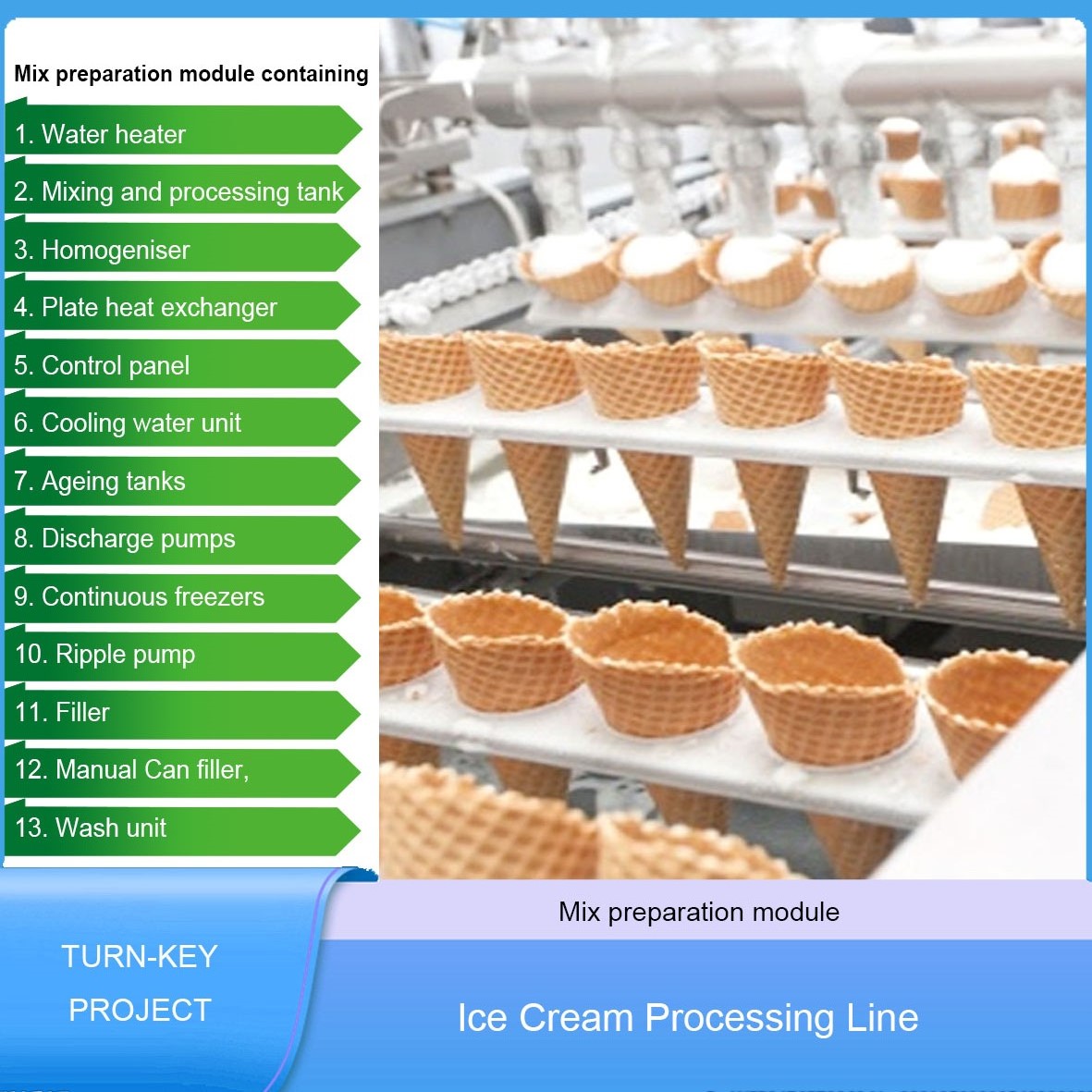

Figure shows ice cream products production line.

1. Ice cream mix preparation module containing

2. Water heater

3. Mixing and processing tank

4. Homogeniser

5. Plate heat exchanger

6. Control panel

7. Cooling water unit

8. Ageing tanks

9. Discharge pumps

10. Continuous freezers

11. Ripple pump

12. Filler

13. Manual Can filler,

14. Wash unit