To watch more videos about this machine, please check our youtube channel:

https://www.youtube.com/channel/UCs-MbMT4Pu0HseoNwFjWCgQ

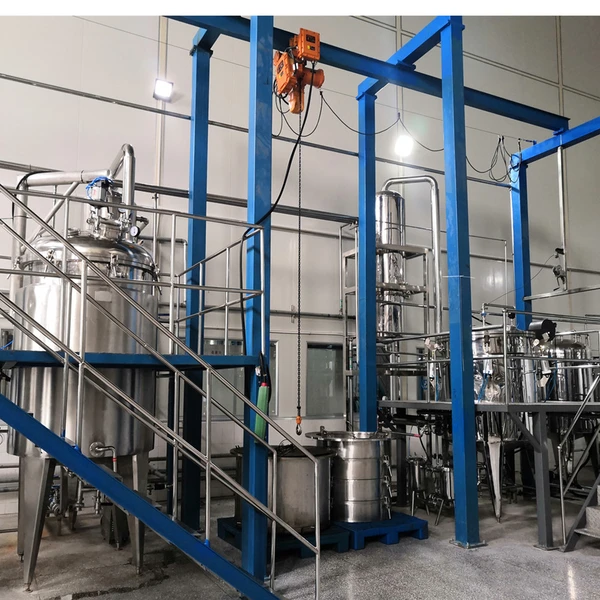

For big size essential oil distillation machine, we have two types for customers choice:

up loading and up discharging

up loading and down discharging

1000L essential oil distiller Technical Parameter:

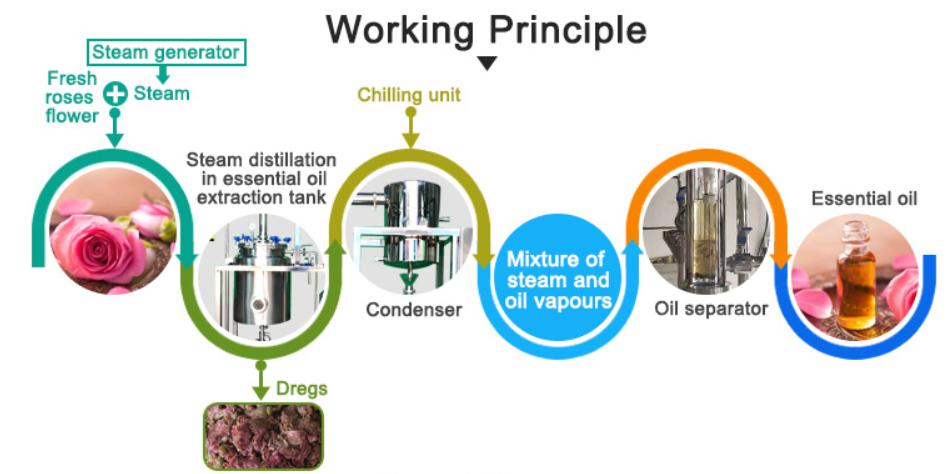

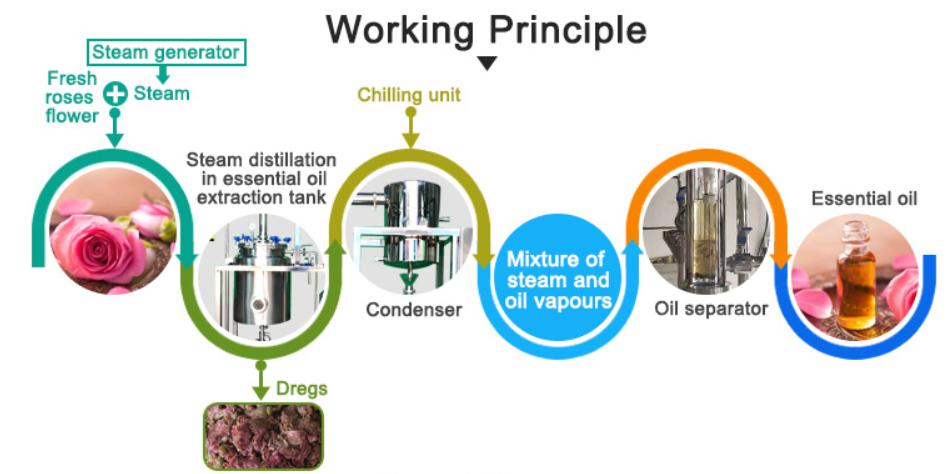

1. Heating type:Steam generator

2. Volume of extracting tank: 1000L

3. Distillation basket:600L

4. Condenser: Coil type, 300 mesh,condensing area 0.85 ㎡

5. Extracting temperature: Indoor temperature to 100℃

6. A Electric heating power: 15.5kw(conducting oil heating system)

7. Pipeline Filter: Filtering capacity: 1000kg / h;filtration precision: 150 to 250 mesh

8. Cooling media:Water,3T/h(customers can choose 3P chiller as needed)

9. Temperature transducer: PT-1000

10. Temperature control module: Taiwan LAHO

11. B Temperature control system: Siemens temperature control steam proportional valve group

12. Temperature control:A with automatic control and B through shutoff valve manual control or proportional valve automatic control

13. Equipment Material:Whole equipment using excellent stainless steel SUS304,thickness 3mm

14. Distillation tank: 2 layers stainless steel(electric heating 3 layers)

15. Water separator material: Borosilicate glass

16. Size:L7600xW9500xH4300m

up loading and up discharging type:

up loading and down discharging: