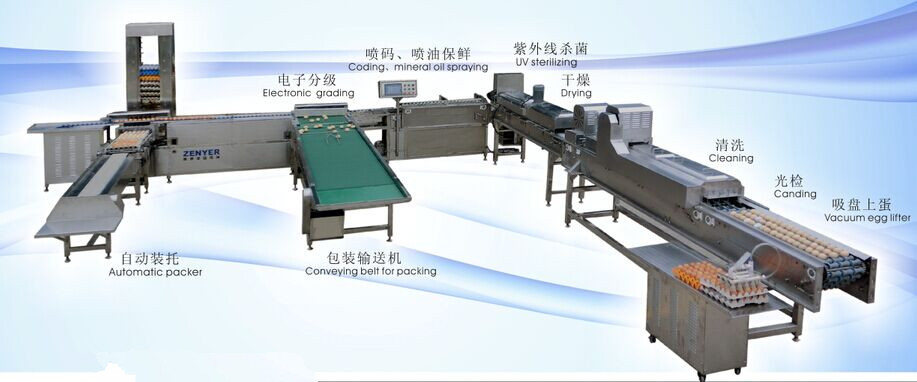

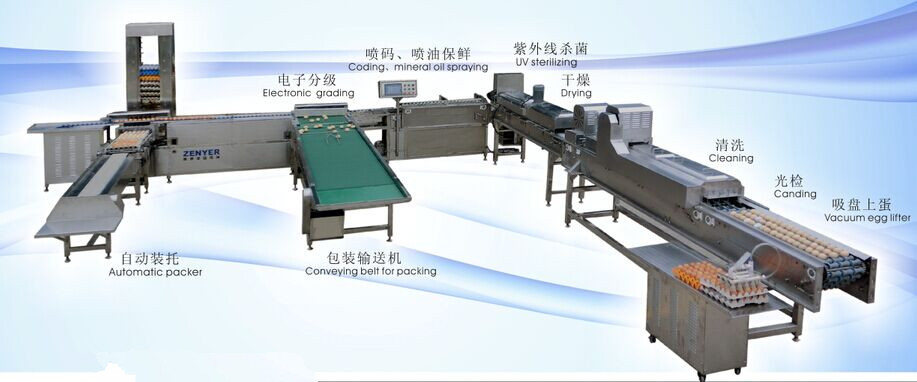

egg cleaning sorting packing line

| Commodity | hot sale chicken egg processing equipment poultry egg automatic packaging machine |

| Product code | 302A |

| Capacity | 2000-100000pcs/h |

| Material | stainless steel 304 |

| Voltage | 380V, 50HZ, 3-Phase |

| Powet | 9.2KW |

| Net weight | 1600 KG |

| Dimension | 15.7 * 6 * 2 M |

| Structure | strong,durable,detatchable,replaceable,easy to learn |

| Function | egg grading , cleaning , drying ,coding , candling ,UV sterilizing , automatic packing |

Main function:

*Handle egg: adopts negative sucker feeding egg. Hand don’t touch egg to minimize infection.

*Disinfection: Use disinfectant spray eggs, kill pathogenic bacteria and microorganisms

*Cleaning: Use hot water and secondary four brush scrub eggs, to ensure that the egg surface clean

*Drying: USES the high pressure air blower, quickly remove moisture on the surface of the egg

*Printing: Eggshell label production date, batch and trademark, etc

*oil injection: In eggshell spraying a layer of protective film, covering the wool stoma, prevent bacteria to enter and prevent

moisture loss, the purpose of keeping fresh.

*sterilization: The c-band ultraviolet disinfection again on egg surface, sterilization equipment belt, at the same time reduce

the secondary pollution

*Light check: Using LED light source illuminate, detect unqualified eggs to the naked eye

*Grading: Determined by weight egg big, medium, and small level (at most) can be divided into 5 levels, tooling box packaging

Automatic duck egg cleaning grading line

1. Egg in the water: pour the whole basket of eggs into the sink, and the eggs will be transported up the slope automatically

through the conveyor chain.

2, high pressure spray: in the process of conveying by high pressure spray water, can spray on the temperature, spray on the

surface of the egg disinfectant.

3, brush cleaning: after the water spray into the brush cleaning, the egg in the process of transmission to ensure rotation, and

use the brush to brush the egg in all directions.

4, light inspection: use special light source and mechanical structure, transmission of eggs, can be checked not fresh eggs,

impurities, bubble eggs and other defective eggs.

5. Drying system: mechanical brushing and low-temperature drying are adopted to remove water attached to the surface of the egg.

6. Electronic grading (also with mechanical grading) : using an electronic control system, eggs can be divided into 5 or 7 grades

according to different weights, from large to small.

7. Egg receiving in water: egg receiving baskets can be configured after grading and eggs receiving in water to save labor and

reduce production costs.

The cleaning line adopts the modular design, which can be selected according to the customer's production process for the

transition on the egg + grading equipment, optical inspection system and drying system.