HPP Machine For Juice

Ultra high pressure HPP processing sterilizer machine

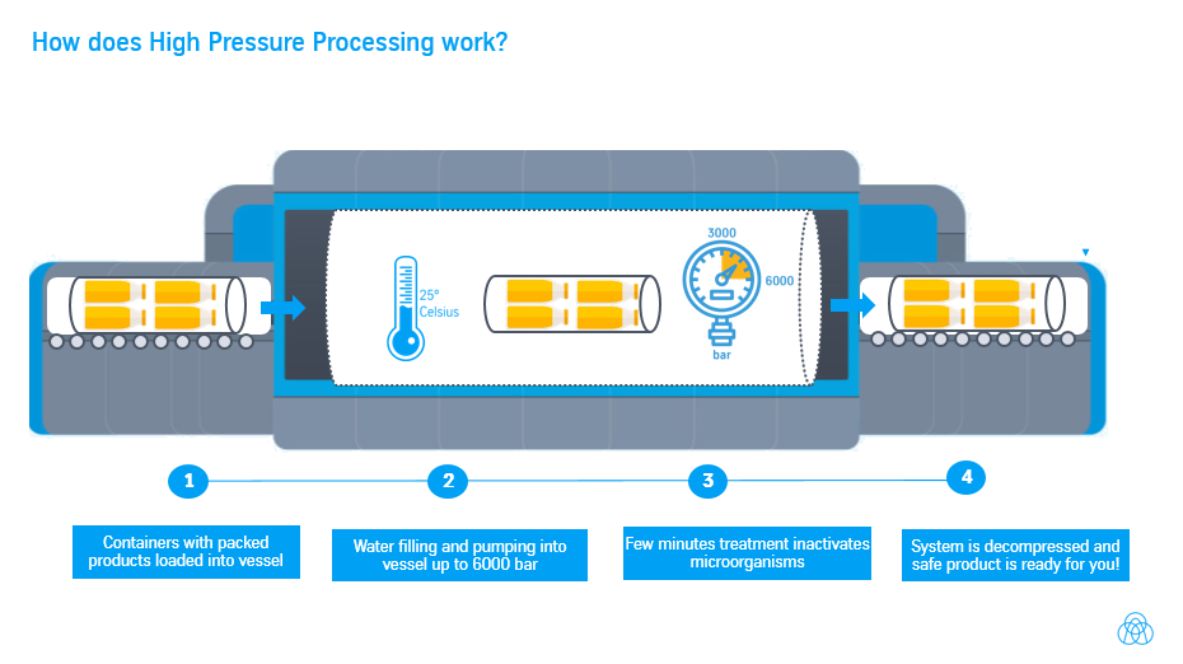

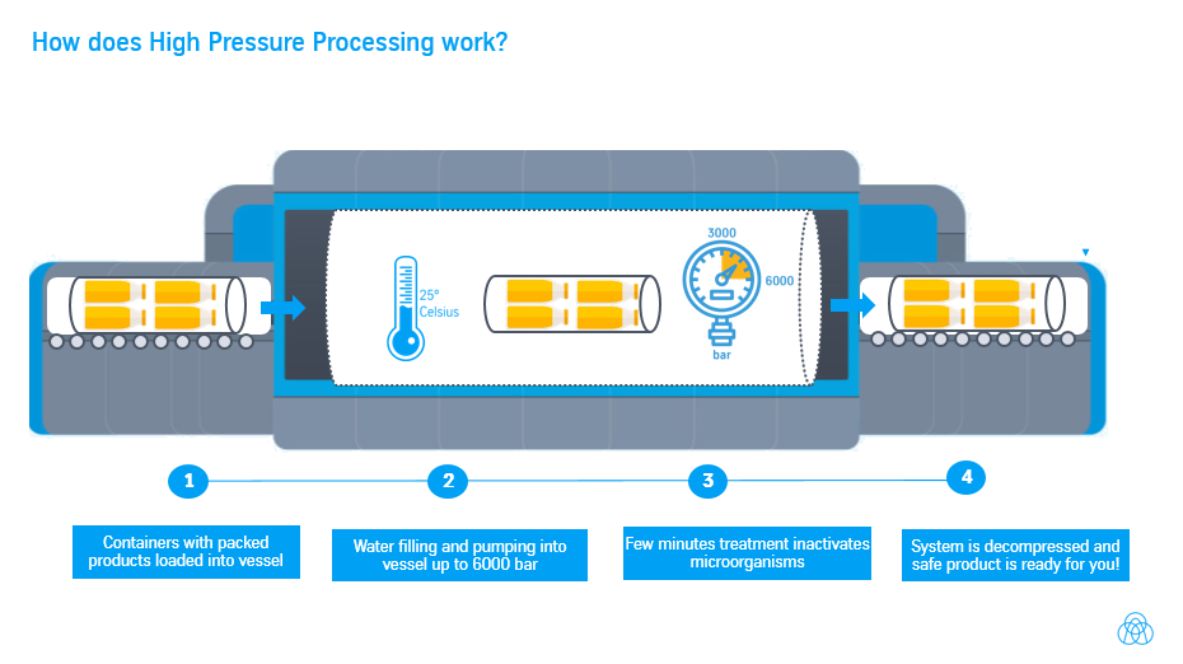

WHAT IS HIGH PRESSURE PROCESSING(HPP)?

High Pressure Processing (HPP) is a cold pasteurization technique by which products, already sealed in its final package, are introduced into a vessel and subjected to a high level of isostatic pressure (300–600MPa/43,500-87,000psi) transmitted by water.Pressures above 400 MPa / 58,000 psi at cold (+ 4ºC to 10ºC) or ambient temperature inactivate the vegetative flora (bacteria, virus, yeasts, moulds and parasites) present in food, extending the products shelf life importantly and guaranteeing food safety.High Pressure Processing respects the sensorial and nutritional properties of food, because of the absence of heat treatment, and maintains its original freshness throughout the shelf-life.

High Pressure Processing Technology (HPP) Main Advantages

• Characteristics of the fresh product are retained, sensorial and nutritional properties remain almost intact: Greater food quality.

• Destroys pathogens (Listeria, Salmonella, Vibrio, Norovirus, etc.): Food safety and exportation.

• Extends product shelf life: Lower returns, improved customer satisfaction.

• Reduces drastically the overall microbiological spoiling flora: Higher quality along shelf life.

• Avoids or reduces the need for food preservatives: Clean label foods (Natural/Additive Free).

• New innovative food propositions. Products that can not be thermally treated can now be High Pressure Processed: Innovation and competitive advantages.

• Able to shuck molluscs or extract crustacean meat without boiling: Higher yields, fresh flavour, minimum hand labour.

Genyond has a complete product line which include from small lab testing to industrial mass Production processing,

the pressure vessel capacity from 2 liters up to nearly 800 liters for College,institute and Food&beverage manufactory,

usable with water medium maximum Standard operating pressure at 87,000 psi(600 MPa.).

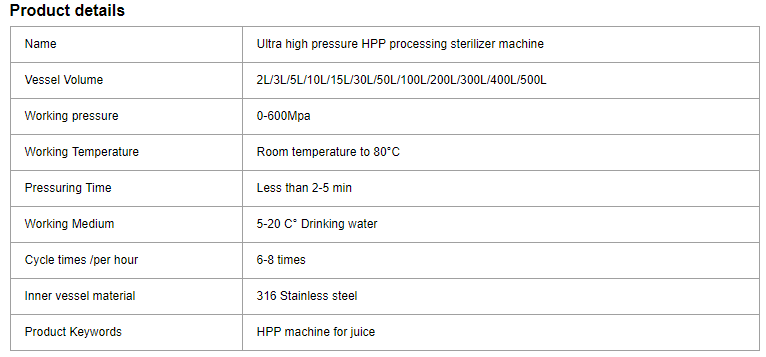

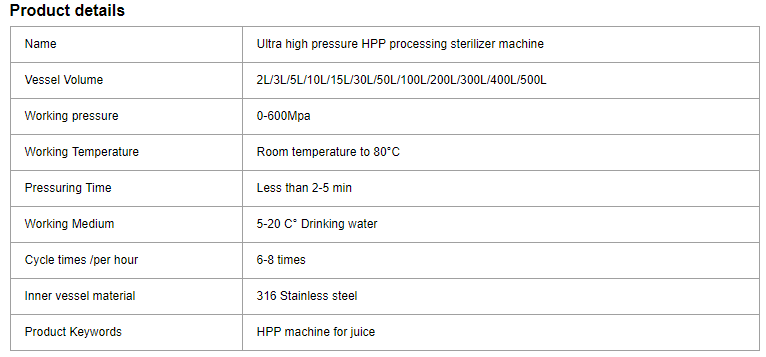

Genyond HPP machine specification as follows:

1.Experimental Model:

HPP600MPa, 2L/3L/5L/10/15L –ID∅ 120mm-160mm/Vertical or Horizontal Frame(No screw)

2.Medium-sized Trial Production

Model: HPP600MPa, From 30L/50L/100L –ID∅ 160mm-300mm/Vertical or Horizontal Frame(No screw)

3.Large-sized Production

Model: a.The Single vessel:HPP600MPa, 100L/200L/300L/400L/500L

b.The Double vessels:HPP600MPa, 2X100L/2X200L/2X300L/2X400L/2X500L

Horizontal Fram/ID∅ 200mm-400mm(No screw)