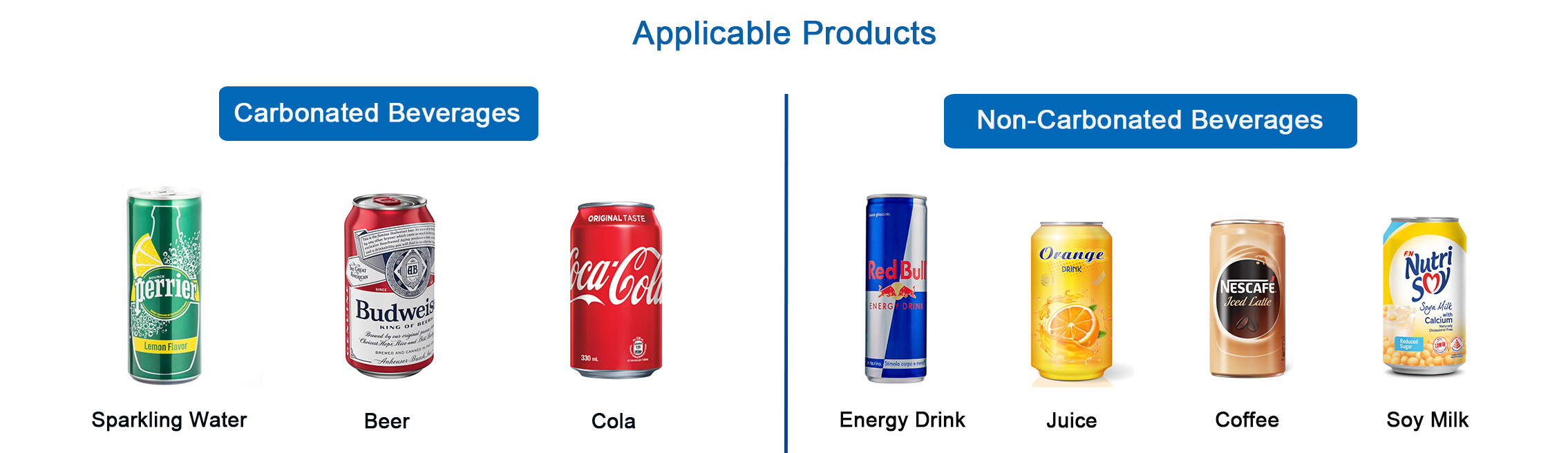

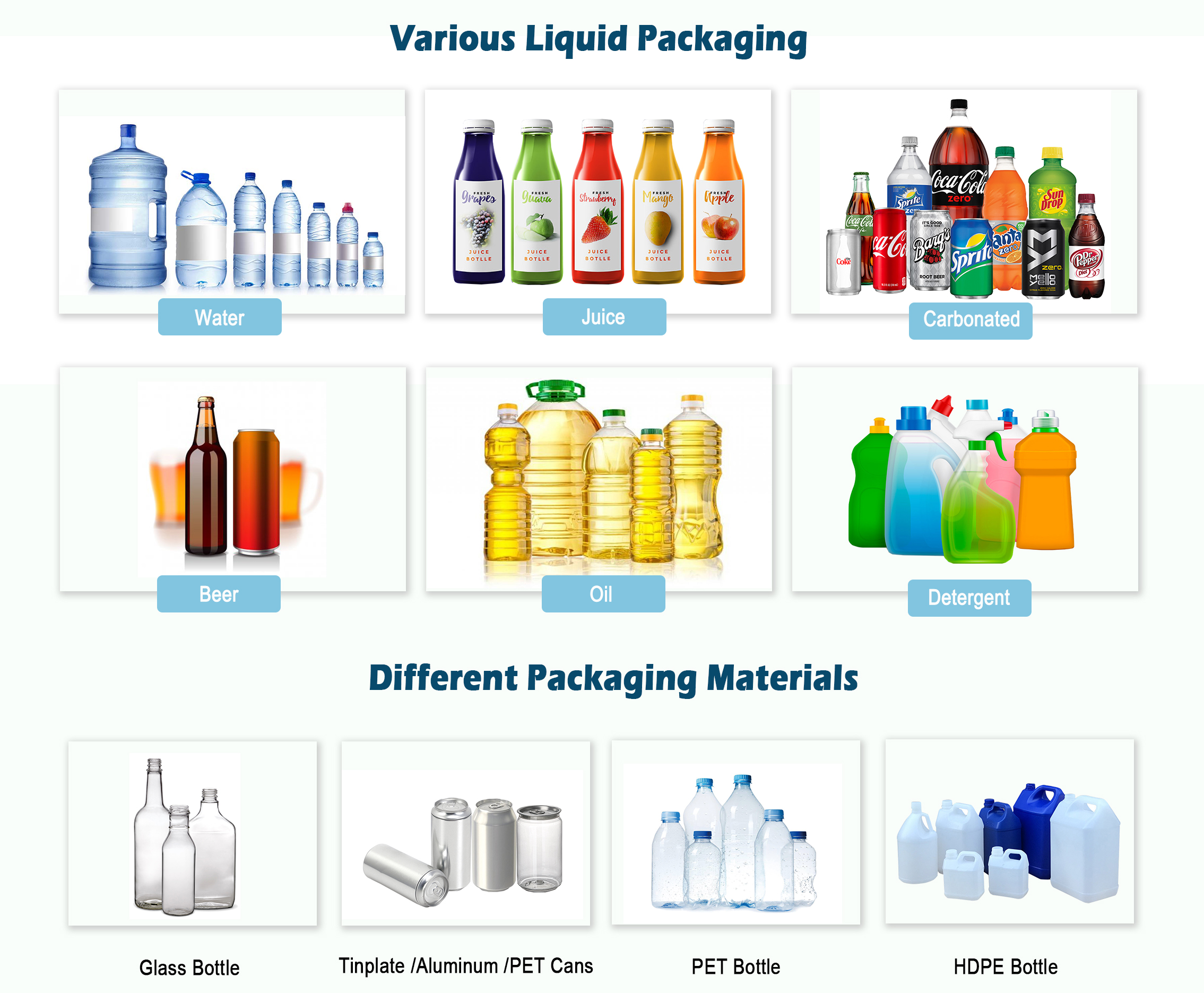

We provide the complete Can filling and package solution ,from can depalletizer ,can rinsing machine ,can filling & sealing monoblock machine ,leakage check,liquid nitrogen dosing machine ,pasteurizer tunnel ,blow dryer ,carton package ,film package system ,which is widely used for the beverage ,beer ,Juice industry and so on.

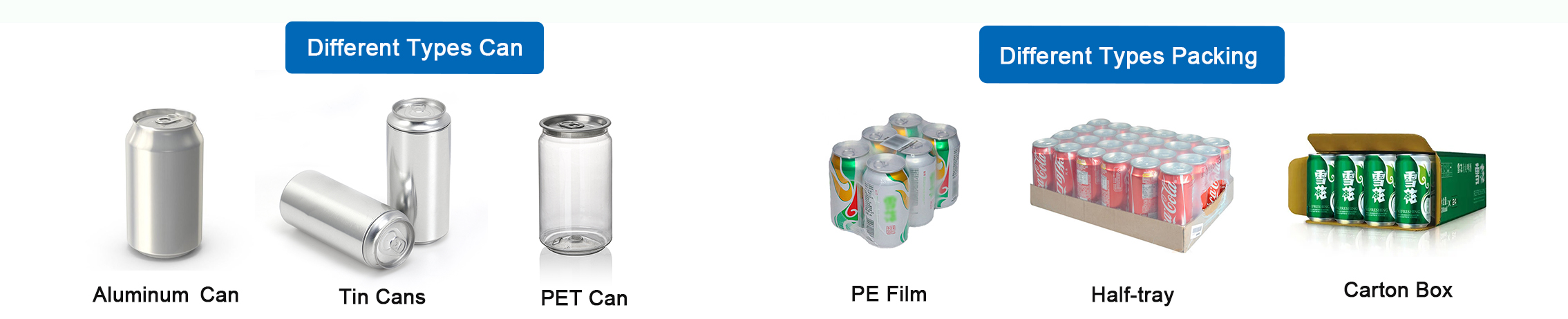

Types of can: Aluminum cans,Tin cans,PET cans etc

Filling Range: 130ml, 250ml, 330ml, 355ml, 500ml, 12oz, 16oz, 1L and so on (0.1-1L)

Capacity: 4000BPH, 8000BPH, 12000BPH, 16000BPH, 20000BPH