Vacuum freeze drying technology is the most advanced technology for food dehydration processing at present. Compared with the common drying method, the freeze-dried food produced with this technology features long period of quality assurance, good re-hydration nature, good-looking color, good flavor, taste, shape and high content of nutritious components. The dried food basically remains unchanged in its volume and shape, it looks like sponge and has no shrinking. This kind drying technology can be widely used in process of vegetables, fruits, condiments, aquatic products, biological products, medicine, beverage and etc.

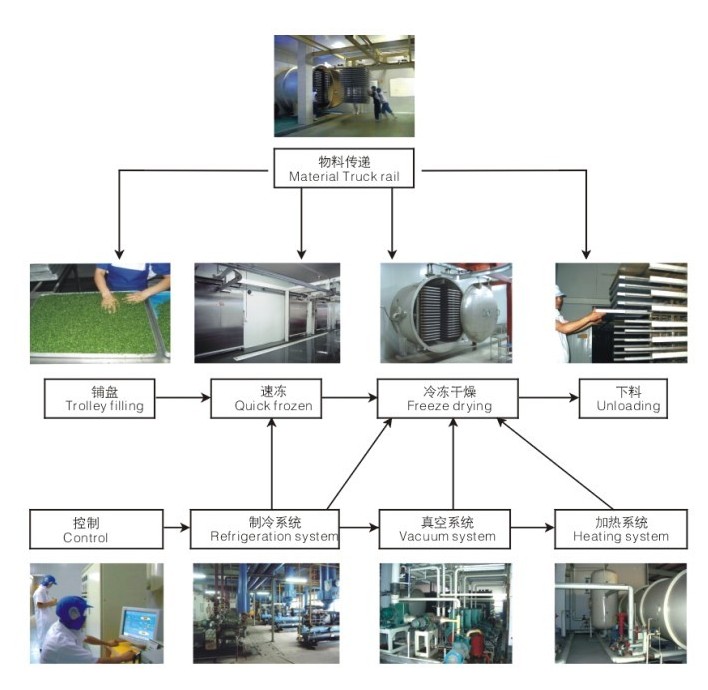

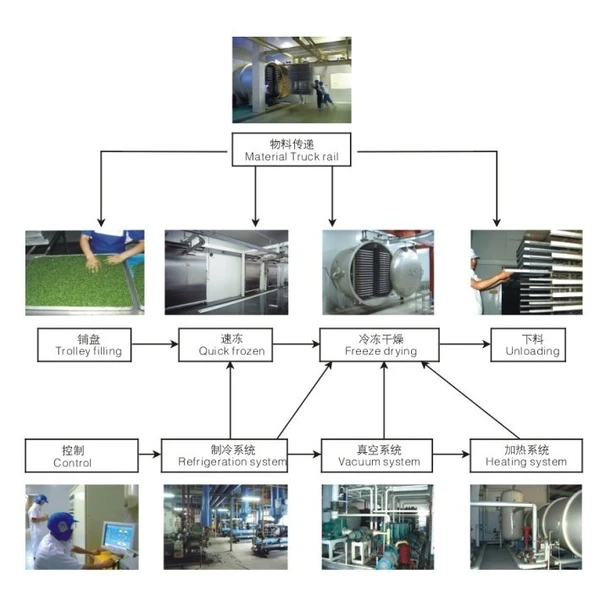

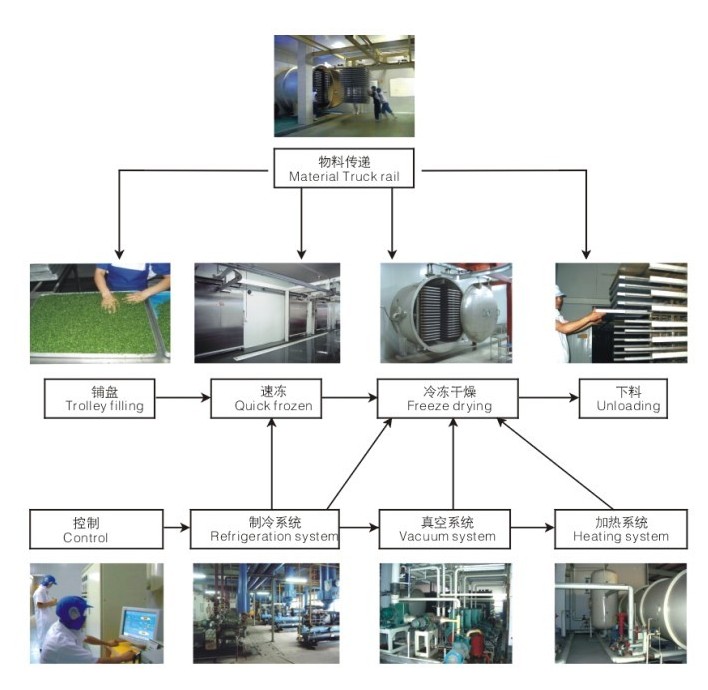

Working principle of vacuum freeze dryer

Instead of traditional vaporization dehydration method, the vacuum freeze drying technology is dehydrate products by sublimation directly from ice to vapor. During the Freeze drying process, the materials will be frozen to -18°c, then move into the vacuum drying tank for dehydration, automatic control system will set the vacuum and heating temperature according to the freeze drying cirve of each products to maintain the proper circumstances for FD processing. The materials stay in frozen status during the drying process and water vapor will be condensed on the surface of cold trap coils to absort the water out from the materials.

Application

The vacuum freezing and drying machine can be widely used in various fields, such as vegetables, fruits, condiments, seafood, biological products, medicine, beverage, specimen, etc.

Technology Parameter

Parameters | Model | FDGY-0.5 | FDGY-10 | FDGY-20 | FDGY-50 | FDGY-100 | FDGY-150 | FDGY-200 | FDGY-280 |

Drying area (m2) | 0.5 | 10 | 20 | 50 | 100 | 150 | 200 | 275 |

Mean dehydrating amount (kg/h) | 5-6 | 100 | 200 | 500 | 1000 | 1500 | 200 | 2750 |

Size of material tray (m) | 310×540×30 | 745×635×30 | 435×555×30 | 540×635×30 |

Number of material tray (pcs) | 3 | 21 | 80 | 144 | 288 | 480 | 576 | 792 |

Size of pot (M) | 1.5×1.6×1.6 | φ1.4×2.1 | φ1.8×2.4 | φ2.4×4.8 | φ2.4×8.9 | φ2.4×12.8 | φ2.4×16.6 | φ2.4×21.9 |

Operation vacuum (pa) | 13.3~200 | 26.6~200 |

Heating plate T (°C) | Normal temperature~+120°C |

Electric heating (Kw) | 2 | 21 | 40 |

|

|

|

|

|

Steam consumption (Kg/h 0.7Mpa) |

|

|

| 140 | 270 | 450 | 540 | 750 |

Cold load consumption (Kw) | 1.5 | 21.6 | 36 | 90 | 180 | 280 | 360 | 490 |

Installed power (Kw) | 6.5 | 55.8 | 104.5 | 41.2 | 69.7 | 92.5 | 117.5 | 125.5 |