Pectins are natural carbohydrates (polysaccharides) contained in plants. Basically, the substances are concentrated in fruits. They constitute structural components of tissues, maintain the turgor, tone of fruits, as well as ensure their preservation and resistance to drought. They are present in the cell sap of fruits and vegetables making up more than half of their cell mass. Pectin production consists in disintegrating the cell membranes and obtaining the polysaccharides enclosed therein.

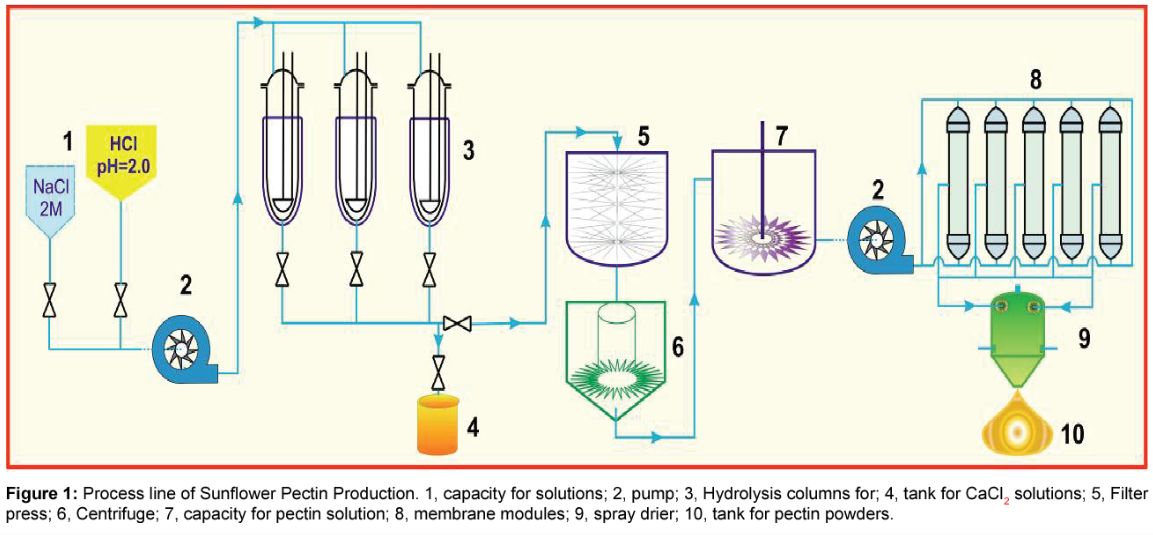

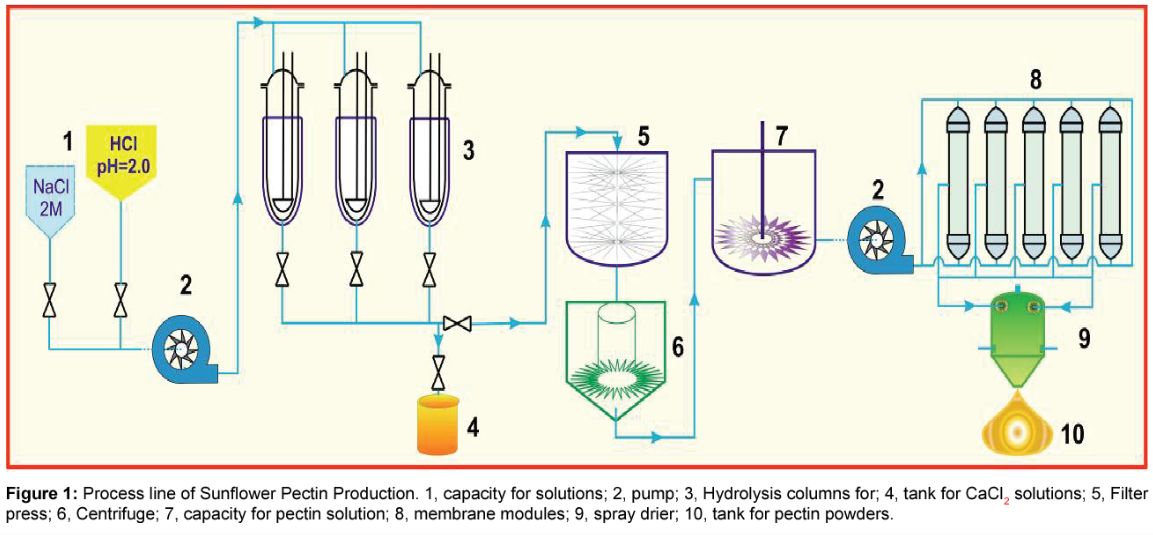

Technological scheme for the dry pectin production

Raw material: apple pomace

* Apple pomace crushing

* Drying

* Pomace storage

* re-crushing

* Extraction

* Pressing

* Adding sugar

* Filtering

* Concentrating in vacuum

* Pectin sedimentation

* Pectin separation using filter

* Drying in vacuum drying machine

* Alcohol catching machine

* Grinding in the ball mill

* Packing

* Alcohol distillation

* Reflux fermentation

* pumps

Application of pectin:

1.Pectin is made from apple residue by acid extraction and alcohol precipitation. The influence of acid type on the yield of the product was discussed, and the influence of acid concentration, ratio of material to liquid, heating temperature and time on theyield of the product was studied with hydrochloric acid as the representative, and the extraction conditions of pectin in apple dregs were determined. The products have been tested by relevant departments, and they meet the quality standards of pectin. The production cost has also been estimated.80% ~ 90% of the pectin produced by industry is used in the food industry to make jelly, jam and jelly. It can also be used as hemostatic agent and substitute plasma in medicine, and can also be used to treat diarrhea and heavy metal poisoning.

2. Asemulsifying stabilizer and thickener, it can be used in all kinds of food according to the regulations of our country.

3. It ismainly used for toning water, acidic tooth powder, etc., because it is not stable in alkaline medium, it cannot be used for alkaline cosmetics. Pectin is non - toxic, non - irritating, can be used in the mouth of cosmetics, such as lipstick. It can also be used as thickener and binder of toothpaste.