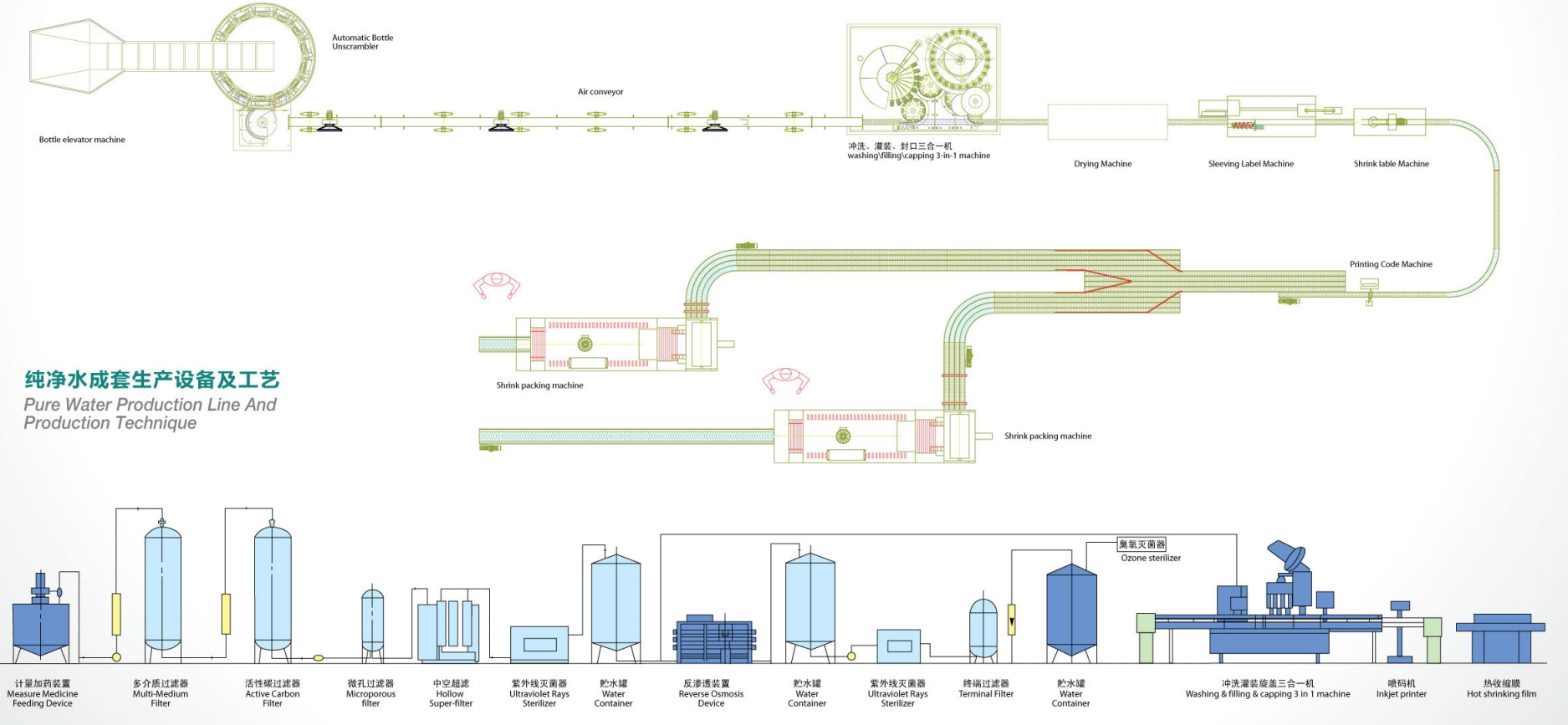

Process of juice beverage production and filling line

Raw water → raw water tank → booster pump → activated carbon filter → ion softener → precision filter → reverse osmosis unit → ultraviolet sterilizer → pure water tank → pure water pump → automatic filling line → high-speed shear tank → high-temperature pump → sugar → high-temperature pump → syrup filter → blending tank Tank → vacuum degassing machine → temporary storage tank → ultra-high temperature instantaneous sterilization → fully closed heat preservation tank → hot filling and blowing machine → automatic bottle machine → three-in-one machine → lamp detector → inverted bottle sterilizer → spray cooler → automatic set of standard shrinker, strong dryer → inkjet printer →PE film packing machine (packing machine)